The Febco Series 825Y Reduced Pressure Zone Assemblies are used to protect against high hazard (toxic) fluids in water services to industrial plants, hospitals, morgues, mortuaries, and chemical plants. They are also used in irrigation systems, boiler feed, water lines and other installations requiring maximum protection. They feature a bronze body and threaded ball valve shutoffs. Maximum Working Pressure: 175psi (12.1 bar).

WARNING!

Irrigation systems supplied by domestic or private potable water systems are considered to be a potential pollution hazard to the water supply. These systems must include protection to prevent possible backflow of irrigation water into the potable water supply.

Federal law requires a proper backflow device to be installed on any watering system to prevent contamination of the supply; whether it be pump or city water. Check your local water authority for installation requirements & codes. In many rural areas; specific requirements for landscape irrigation systems may not be covered in local plumbing codes and/or enforcement may be limited. HOWEVER...limitation in local authority does not alter the basic requirement for protection of the potable water supply.

Approvals-Standards

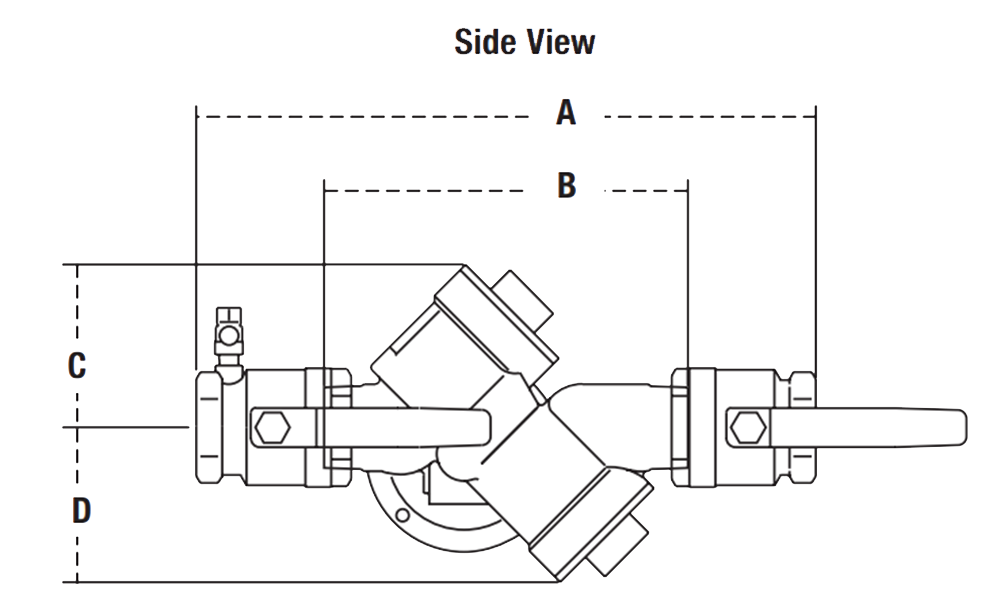

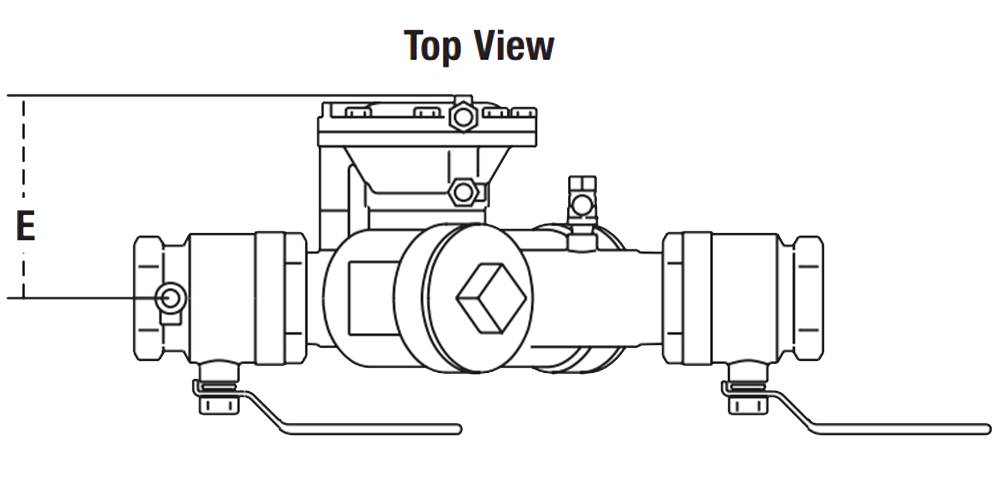

| SIZE | DIMENSIONS | WEIGHT | ||||

|---|---|---|---|---|---|---|

| IN. | A IN INCHES | B* IN INCHES | C IN INCHES | D IN INCHES | E IN INCHES | LBS. |

| 3/4 | 12 | 7 3/4 | 3 1/4 | 3 1/4 | 4 | 11.5 |

| 1 | 12 3/4 | 7 3/4 | 3 1/4 | 3 1/4 | 4 | 12.5 |

| 1 1/2 | 17 | 10 1/2 | 4 1/2 | 4 1/2 | 5 | 26.5 |

| 2 | 17 3/4 | 10 1/2 | 4 1/2 | 4 1/2 | 5 | 29.0 |

* B Dimension is less shutoffs. Weights shown are approximate. Dimensions shown are nominal, allowance must be made for normal manufacturing tolerances.

The reduced pressure zone assembly is built out of durable bronze material and includes threaded ball valves with a maximum pressure of 175 PSI. This product meets the specifications of AWWA, ASSE, CSA and approved by the Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. The Febco 825Y RPZ Backflow Preventer features a modular relief valve and replaceable seat rings of all sizes for easy routine maintenance. The "Y" shaped check valves are spring-loaded and the RPZ has internal relief valve pressure sensing passages. The end connections are NPT ANSI/ASME B1.20.1. The internal parts of this product are in line for easy access and repair.

Like many backflow preventers, the RPZ assembly is a valuable part of the sprinkler system that can be fragile under freezing temperatures. Winterizing the backflow device can be done in six easy steps starting by turning off the water supply for the sprinkler system. Next, make sure that the ball-valve controlling the incoming water is closed and the ball-valve controlling the water going out to the sprinkler system open. Locate the test cocks and remove any caps of protective covers from the ports. Locate the adjustment screw on the side of the test cock and turn it approximately one-quarter and leave the screw in the 45° position. Finally, turn the ball-valves to a 45-degree angle. If you're looking for more protection, insulating your exposed device with a backflow pouch can be valuable.

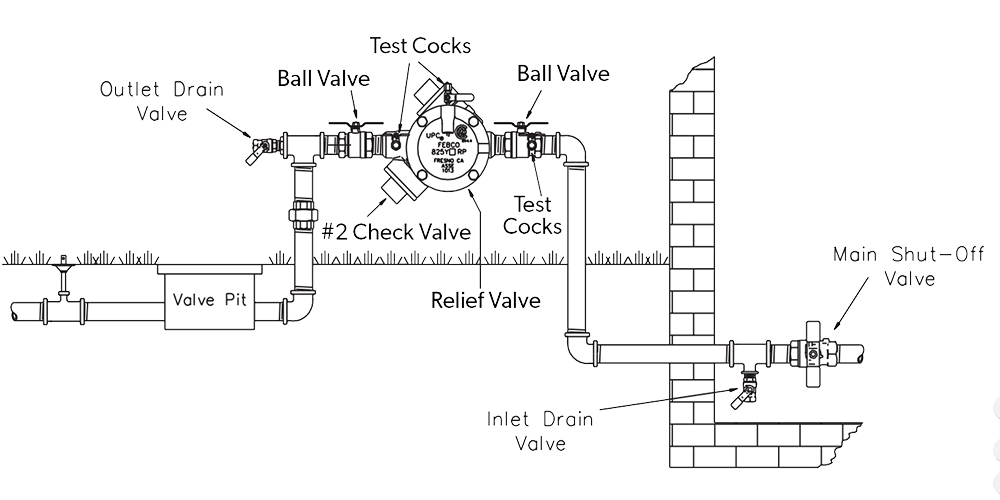

An RPZ is commonly installed in either a job-built concrete vault or two twelve-inch deep valve boxes stacked vertically with bottoms together. Dig a hole at least twenty-six inches deep and three inches larger at the bottom than the dimensions of the top of a box. Glue a PVC drain fitting into a 1-1/2″ sanitary street quarter bend and set with the top of the drain resting on the surface of the rock. Install the reduced pressure zone assembly inline between the holes in the bottom valve box.

In accordance with federal law, a backflow device must be installed for use with any watering system to help prevent contamination of the water supply. It is recommended that customers check their local water authority for installation codes and requirements. In rural areas, the exact regulations for landscape sprinkler systems may not be covered in local plumbing codes and enforcement of those regulations may be limited.

The Febco 825Y series RPZ is used to protect the water system against high-hazard fluids. These devices are commonly installed for industrial plants, hospitals, morgues, mortuaries, and chemical plants. RPZ Assemblies can also be used in irrigation systems, boiler feed, water lines, and other installations that require maximum protection against toxins.

Winterizing an RPZ that is installed above ground can be done the same way as the pressure vacuum breaker and the double-check valve assembly. The first step to winterization is to turn off the water supply and adjust the test cocks. When these steps are finished it is recommended to cover the device with an insulated backflow pouch to protect against further freeze damage.

Replacing the entire RPZ with a new one is a simple process. First disconnect the assembly section at the unions, and duplicate the section using a new reduced pressure zone assembly, pipe, and fittings. Then reconnect, test for leaks, and call for an inspection. If the RPZ is underground, make sure underground installation is still allowed under local codes. If repairs are necessary then each RPZ comes with specific instructions for maintenance and repair.

| Brand | Febco |

|---|---|

| Product Type | Reduced Pressure Zone Assemblies (RPZ) |

| Test Cocks | 4 FEMALE |

| Max Working Pressure | 175 PSI |

| Hydrostatic Test Pressure | 350 PSI |

| Temperature Range | 32F to 140F |

| Main Valve Body Materials | Bronze |

| Relief Valve Body | Bronze |

| Elastomers | Nitrile |

| Diaphragms | Nitrile, Fabric reinforced |

| Springs | Stainless Steel |

| Warranty | 1 Year |

| Size | 3/4 in. |

| Connection | FPT |

| Lead Free | Not Lead Free |