FEBCO® Series 765 Pressure Vacuum Breakers are designed to be installed to provide protection against back siphonage of toxic or non-toxic liquids. They feature a durable bronze body and a check valve and air opening port in one assembly.

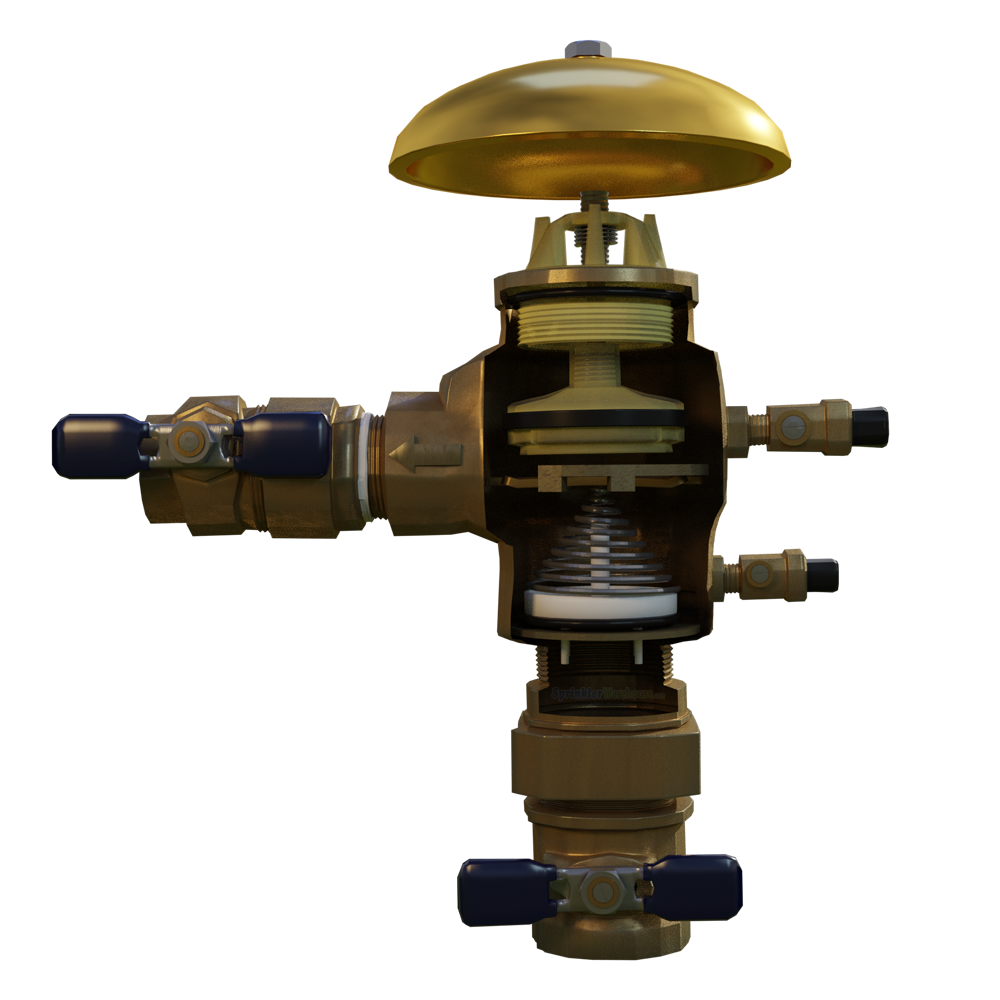

Pressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent the backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring-loaded check valve that closes tightly when water flow through the assembly drops to zero, and a single air relief valve that opens to break the siphon when the pressure drops to 1 PSI.

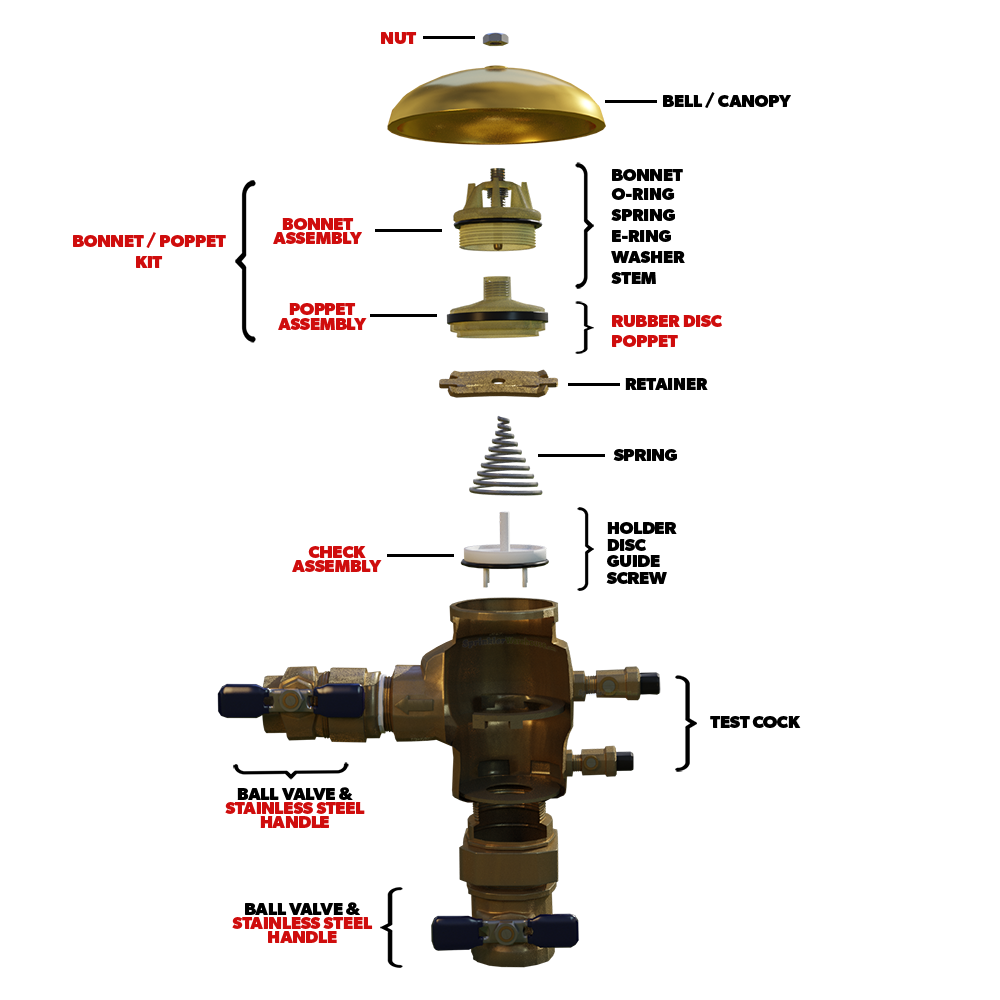

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet, and bonnet assembly shall be constructed of engineered plastic to protect the valve body from freeze damage. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12" (300mm) above the highest downstream outlet and the highest point in the downstream piping.

The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F to 140 degrees F. The assembly shall meet the specifications of the USC - FCCC & HR Manual. Pressure Vacuum Breaker assemblies shall be FEBCO® Series 765 or prior approved equal.

Materials

WARNING!

Irrigation systems supplied by domestic or private potable water systems are considered to be a potential pollution hazard to the water supply. These systems must include protection to prevent possible backflow of irrigation water into the potable water supply.

Federal law requires a proper backflow device to be installed on any watering system to prevent contamination of the supply; whether it be pump or city water. Check your local water authority for installation requirements & codes. In many rural areas; specific requirements for landscape irrigation systems may not be covered in local plumbing codes and/or enforcement may be limited. HOWEVER...limitation in local authority does not alter the basic requirement for protection of the potable water supply.

*Red indicates repair parts sold at the Sprinkler Warehouse

The Febco 765 series is designed to protect against possible back-siphonage into the water supply. These devices feature a strong bronze body as well as a check valve and air opening port in the assembly. These devices are designed for minimum head loss as well as a lightweight poppet that seals the air opening under minimum flow conditions. The maximum working pressure for this product is 150 PSI.

The first step in installing a PVB device is to check with the local codes for backflow device requirements and restrictions. The installation site must be easily accessible for routine testing and maintenance to ensure the system is operating properly. Prior to installing this backflow device, the supply line must be flushed with all foreign material. Pressure Vacuum Breaker assemblies must be installed at a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. For detailed instructions on proper installation please visit our Sprinkler School video library.

The assembly includes two resilient seated shut-offs and two seated test cocks. The spring-loaded check valve and air inlet valve are constructed to allow routine maintenance of the device. The device includes a bronze body for durability. The check, poppet, and bonnet assembly are made of engineered plastic to protect the valve body from freeze damage. Details on winterization and tips to keep your device protected can be found at Sprinkler School.

Sprinkler irrigation systems that are supplied by either domestic or private potable water systems have the potential to be pollution hazards to the water supply. According to federal law, it is required that these systems be protected with the installation of a backflow device to protect against possible back-siphonage into the potable water supply. Sprinkler Warehouse encourages our customers to check their local water authority for installation requirements and codes.

The Febco 765 backflow device is available in a variety of sizes at Sprinkler Warehouse. These sizes include the popular 1 inch FPT, the 1-inch union end ball valves, the 1-1/4 inch FPT, and the 1/2 inch FPT backflow preventers. Sprinkler Warehouse makes shopping faster and easier than ever with our online free shipping deals and limited-time promo codes.

The Febco 765 backflow preventer should be installed in an area that is accessible for routine testing and maintenance. Refer to local codes for actual requirements in your area. When threading the device inline, place the wrench only on the ball valve hex ends. Keep the sealant off of the interior surfaces of the valve. After installing the device, fill the assembly with water. Then test the valve assembly to ensure that it is operating correctly.

Sometimes the only problem with a PVB device is a worn-out bonnet and poppet. To replace these parts you must first shut off the bottom valve handle by turning it to the right. Then remove all of the broken plastic parts from inside the backflow device. There should not be any plastic pieces remaining inside the device. It is important not to remove the metal piece at the bottom inside the backflow device because it has a spring below it that may hurt you. Replace the parts you removed with the new bonnet and poppet kit. Finally, you need to place the bell on top of the metal screw and tighten the small nut just enough to hold the metal bell on the device and still rotate by hand with some tension. To avoid having to replace the bonnet and poppet again you should cover the backflow device with an insulated pouch to protect against freezing temperatures.

| Brand | Febco |

|---|---|

| Product Type | Pressure Vacuum Breakers (PVB) |

| Test Cocks | 2 FEMALE |

| Max Working Pressure | 150 PSI |

| Hydrostatic Test Pressure | 300 PSI |

| Temperature Range | 32F to 140F |

| Main Valve Body Materials | Bronze |

| Elastomers | Nitrile |

| Springs | Stainless Steel |

| Warranty | 1 Year |

| Size | 1 in. |

| Connection | FPT |

| Lead Free | Not Lead Free |